Do you have a question about this application? Ask our specialists

Contact us

Features & Benefits

Features

- In line with the best available technology

- Wide portfolio

- On-site technical support & optimization

- Safe and easy to use

Benefits

- Achieving legal requirements

- TCO optimalization

Features in more detail:

In line with the best available technology:

- CleanCalco® products offer high efficiency in removing acidic pollutants of chloride, sulphur, selenium, and fluoride.

- Thanks to dual injection with CleanCalco® Depurcal, a significant reduction in pollutant load can be achieved prior to the classic’ flue gas cleaning line.

Wide Portfolio:

- The CleanCalco® product range includes a wide range of products that are engineered for use in most flue gas cleaning systems from wet to dry scrubbing.

- A special range of products for the improvement of boiler cleanliness.

On-site technical support & optimization:

- Carmeuse's experts can help you optimize your process to meet strict legislative requirements and take into account the total cost of operation.

Safe and easy to use:

- Products are ready to use.

- CleanCalco® products are considered as non-ADR product and non-corrosive to the skin (ex. CleanCalco® Q).

Benefits in more detail:

Achieving legal requirements:

- CleanCalco® products are suited and compatible with most existing flue gas cleaning units.

- Dual injection with CleanCalco® Depurcal enables a reduction of pollutants prior to the flue gas cleaning line, resulting in smoother and more efficient operation of the entire line.

TCO optimalization:

- Lower reagent consumption thanks to very high efficiency and technological support from our experts.

- No reagent preparation.

- Lower leachability of fly ash resulting to lower disposal costs or potential reuse in the process.

- High energy recovery due to low temperature efficiency and improved boiler cleanliness when using CleanCalco® products suitable for high temperature injection.

- No increase in CO2 emissions in Scope 1.

- No availability limits and locally produced.

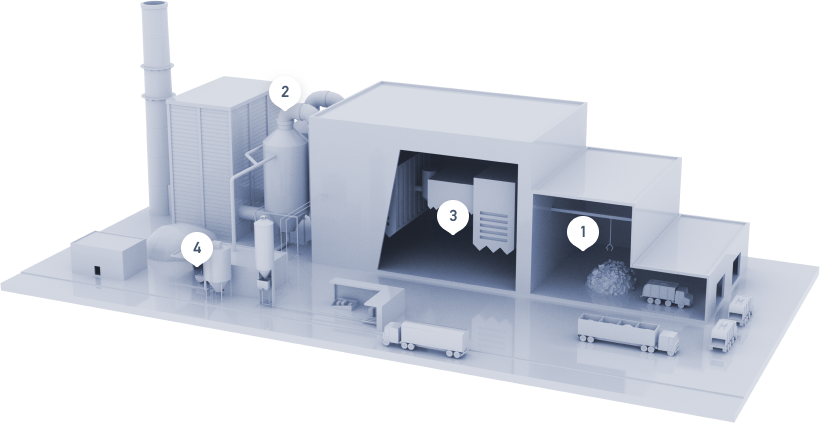

Dedicated solutions for your specific needs

Plant operators face additional costs due to the need to comply with these strict emission limits but are not compensated. Emission control systems should allow for extremely high removal efficiencies while offering full reliability. Redundancy can improve system reliability but significantly increases compliance costs. As a result, multiple factors affect the selection of flue gas cleaning process and significantly affect future system operation. One such influence stems from the specification of the reagent, including its availability and price.

Carmeuse always provides the appropriate CleanCalco® sorbent for whatever process you select. In addition to our product, our range of services enables the optimization of flue gas cleaning during operation, ensuring that compliance costs remain as low as possible.