Do you have a question about this application? Ask our specialists

Contact us

Features & Benefits

Features

Calcium silicate masonry units (CSU) are a manufactured masonry product. Lime and silica-based sand are mixed and then pressed into modular-sized units under high pressure. The “green” units are then subjected to high-pressure steam in an autoclave to produce a masonry unit with uniformly fine-grained texture.

CSU exist in different formats from brick for hand-laying, over block format and even large-sized elements.

Benefits

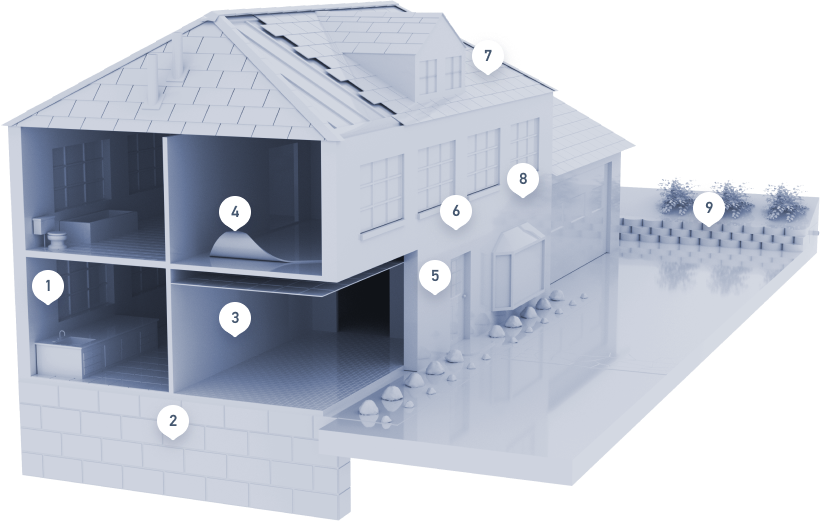

- Environmental friendliness

- High load bearing capacity

- Increased efficiency on construction site

- Compatibility with masonry mortars

- Good sound insulation

- Good heat and humidity absorption

- Fire resistance

Dedicated solutions for your specific needs

High-strength bricks are often needed for heavy load-bearing masonry. External masonry and internal walls usually need thermal and sound insulation, as the designers´ aim is to achieve multiple benefits for the entire building by using the same type of wall-building materials. Masonry needs to be cost-efficient, not only in terms of the bottom line, but also as a building material.