Do you have a question about this application? Ask our specialists

Contact us

Features & Benefits

Features

- Optimized timing additions of flux agents into the volatile steel bath.

- Reduction of phosphorus levels by optimizing the oxidizing environment in the furnace, thus resulting in high quality steel.

Benefits

- Lime and dolime quality and quantity has a direct effect on slag quality, which affects metallurgical results, refractory life, liquid metal yield, and productivity.

- Metallurgical benefits thanks to improved dissolution rate of lime, consistently better slag, lower iron loss, and improved dephosphorization.

- Process benefits include reduced slopping; elimination of re-blows caused by phosphorus; 100% recovery of lime added and potential improvement in refractory lining life.

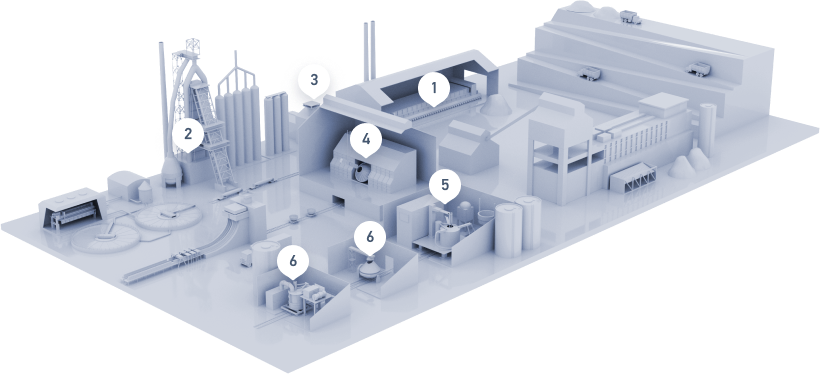

Dedicated solutions for your specific needs

Our Role

While significant results have been achieved through high-quality lime and dolime dosing in BOF, Carmeuse and strategic partners are always looking to further develop this technology for optimum performance.

Carmeuse has developed value in use models to simulate the real effect of lime quality on process efficiency on the steelmaking process. These simulations show how important lime quality is and the significant effect it has on the steel process efficiency including cost, energy efficiency and steel process CO2 emissions. It has been demonstrated that lime quality has a significant impact on the scope 1 CO2 emissions of the steelmaking process.

Lime injection in the BOF converter has been studied through partnerships with world leading injection technology companies to develop and successfully employ lime injection through modified oxygen top blowing lances.