Do you have a question about this application? Ask our specialists

Contact us

Features & Benefits

Features & Benefits

Features

- The AOD slag plays an important role, from decarburization to lowering sulphur levels and reducing expensive oxides back into the metal.

- High purity lime with very low carbon content is required for stainless steel production.

Benefits

- Higher CaO content with stricter controls on impurities helps our customers to achieve reduced lime and dolomitic lime consumption as well as better chromium and silicon recovery.

- Reductions in lime and dolomitic lime consumption further help to reduce slag volumes, thus yielding significant process benefits.

- Our products meet these stringent specifications, which helps our customers to achieve the ideal levels of sulphur and recovery of alloys.

- Our ultra-low carbon lime further helps to avoid carbon pick-up during the refining stage.

Dedicated solutions for your specific needs

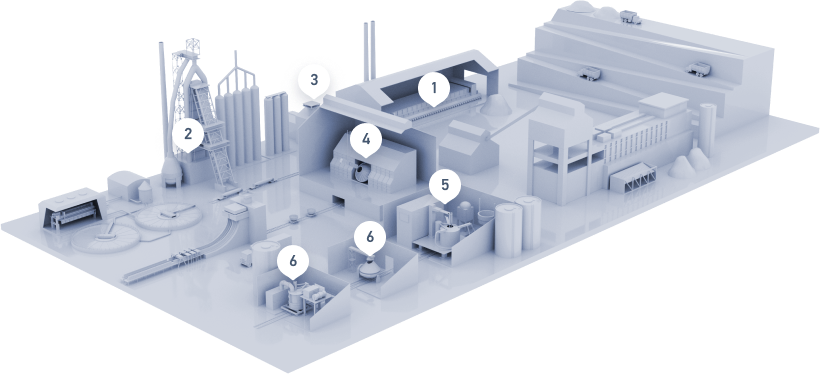

Iron Ore Preparation

Blast Furnace

Hot Metal Desulphurization

BOF Steelmaking

EAF Steelmaking

Steel refining