Do you have a question about this application? Ask our specialists

Contact us

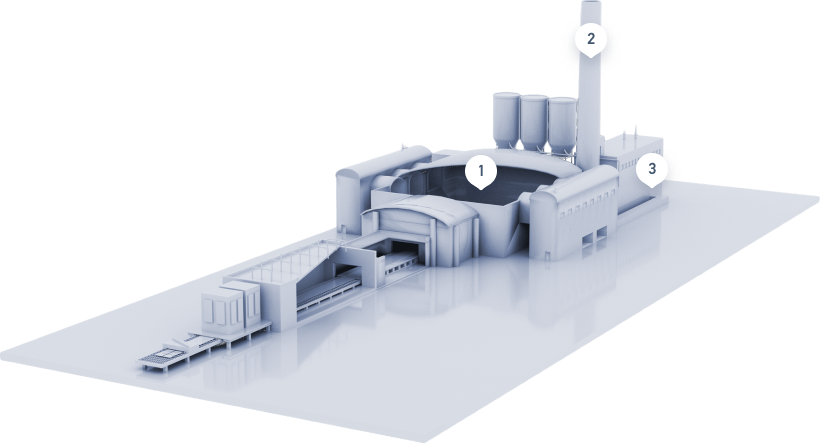

The Process of Flat Glass Production

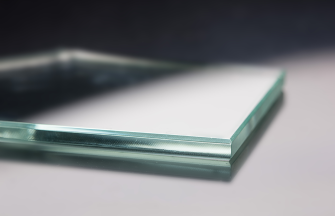

The process of manufacturing flat or float glass, the ubiquitous material used in windows and architectural applications, is a crucial part of many industries. It typically begins with a mix of high-quality raw materials, including silica sand, soda ash, limestone, and sometimes recycled glass, carefully proportioned to create the glass batch. This batch is then continuously fed onto a molten tin bath within a high-temperature furnace, which gives the process its name, "float glass." As the glass flows across the molten tin surface, it spreads uniformly, forming a pristine, flat sheet. The glass gradually cools and hardens as it moves through the annealing lehr, a long oven-like chamber. This controlled cooling process relieves internal stresses, ensuring the resulting glass is strong and distortion-free. Once cooled and solidified, the glass undergoes cutting, shaping, and other treatments to meet specific requirements for architectural and automotive applications. The float glass manufacturing process embodies precision, efficiency, and advanced technology, ultimately delivering the high-quality, transparent, and versatile material we commonly use.

Our Role in Flat Glass Production

What We Do

Carmeuse produces high quality limestone products including ground calcium carbonate which is routinely used in the production of flat glass, playing a pivotal role in enhancing the glass's quality and characteristics. GCC is typically added to the glass batch as a fluxing agent, helping to lower the melting temperature and reduce the energy required during the glass manufacturing process. By stabilizing the viscosity of the molten glass, ground calcium carbonate ensures a uniform and consistent spread of the glass on the molten tin bath, leading to the production of smooth, distortion-free flat glass sheets. GCC also contributes to the glass's optical clarity and transparency, making it ideal for architectural and automotive applications. The use of these materials promotes cost-efficiency, sustainability, and the overall strength of the final product, making them indispensable in the production of flat glass for a wide range of industries.

How it Helps

- Flux in Glass Batch – Limestone acts as a fluxing agent in the glass batch, reducing the melting point of the raw materials and enabling a more energy-efficient melting process.

- Stabilizes Viscosity – Limestone contributes to the stable viscosity of the molten glass, ensuring uniform spreading and forming of flat glass sheets.

- Enhances Transparency – Its inclusion in the glass batch improves the optical clarity and transparency of the flat glass, making it ideal for architectural and automotive uses.

- Strengthens Flat Glass – Limestone's role in stabilizing the glass composition results in strong, durable, and high-quality flat glass, suitable for a variety of applications in the construction and automotive industries.

Lime or Soda Ash Storage & Conveying Systems

High volume production places high demand on your equipment. Carmeuse Systems provides comprehensive equipment and storage solutions for storage and pneumatic transfer of your bulk materials. Our experienced engineers can design tailored solutions, including new lime handling systems and retrofits or upgrades for existing equipment.

Supplying Lime for Various Applications