Do you have a question about this application? Ask our specialists

Contact us

The Importance of Lime and Limestone in Plastic and Rubber Manufacturing

Limestone-based products have been used for decades in the production of rubber and plastics, including PVC. Limestone, chemically known as calcium carbonate, is a stable and reliable filler agent, that has some additional advantages, including densifying the final product and making it less fragile.

Lime products, including calcium oxide and calcium hydroxide, are often used for other purposes in the manufacturing process. Calcium oxide, or quicklime, can be used as a drying agent, and in rubber applications, hydrated lime is used as an accelerant.

Our Role in the Production of Plastics & Rubber

What We Do

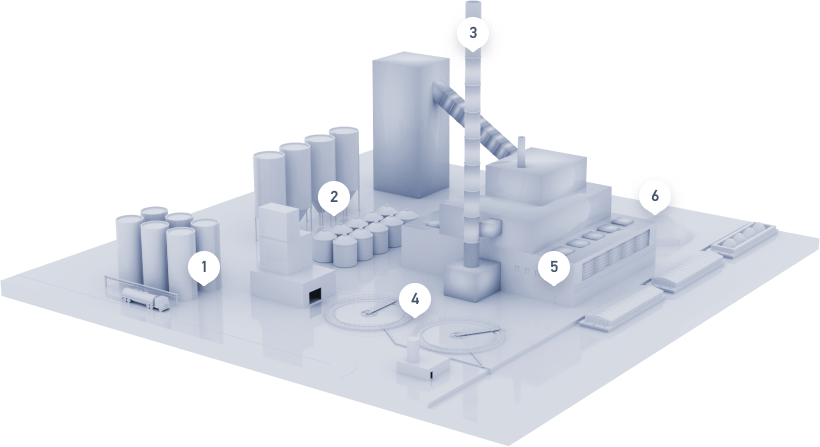

Carmeuse and our affiliates support the needs of plastics and rubber manufacturers from End-2-End.

Calcium-based products are widely used in plastic and rubber manufacturing processes worldwide. Carmeuse lime products, including ground calcium carbonate (GCC), high calcium quicklime, high calcium hydrated lime and CALSAFE® lime slurry, have many uses in the production of plastics, PVC, and rubber, from acting as filling and compaction agents, to high-end customized stabilizing and handling agents.

By understanding your chemical and physical specifications, Carmeuse can recommend a product to meet the needs of your manufacturing process. Carmeuse is also able to provide lime handling equipment, including offloading, pneumatic conveying, and lime slaking systems to help maximize the efficiency of the entire process.

How it Helps

- Consistent Quality – Carmeuse lime and limestone products are routinely tested for quality and consistency, to ensure the right chemistry and physical properties for use in manufacturing processes.

- Use as a Drying Agent (Desiccant) – High calcium quicklime is used as a powerful desiccant in the production of plastics and rubber, providing the maximum calcium content for high reactivity.

- Use as an Accelerant – Hydrated lime is a high-performance powder additive often used as an accelerant in rubber applications.

- Use as a Filler - Milled or ground calcium carbonate (GCC) is widely used as reinforcing filler and for enhancing finish in plastic and rubber production.

- Improving Safety – Lime-based products can be used as stabilizers in plastics, replacing other stabilizers banned due to health risks.

Lime Slaking Systems Upgrades

Over time, equipment at plastics and rubber manufacturing facilities may need updated or replaced due to normal wear and tear or for the integration of new technologies. Carmeuse supplies advanced equipment solutions for lime storage, handling, and slaking through Carmeuse Systems.

Our expert engineers can design the right solution to keep your production processes for plastics and rubber running smoothly, from new lime handling systems and slakers, to retrofits and upgrades for your existing equipment. For additional information related to our lime handling expertise, visit the website.

Supplying Lime for Various Applications