Do you have a question about this application? Ask our specialists

Contact us

The Importance of Ceramic Manufacturing

Ceramic production is of paramount importance in the realm of refractory materials due to the unique combination of properties and durability that ceramics offer. Refractories, which are heat-resistant materials used in high-temperature industrial processes, depend on ceramics for their exceptional thermal and chemical resistance. Ceramics have the ability to withstand extreme temperatures and harsh chemical environments, making them essential components in the lining of furnaces, kilns, and other equipment used in industries like steel manufacturing, glassmaking, and petrochemical processing.

Our Role in Ceramic Manufacturing

What We Do

Carmeuse produces dead burned dolomitic quicklime, under the name Dolopel, which is sold into ceramic manufacturing processes as a filler. Dead-burned dolomitic quicklime is a crucial component in the product of ceramic products, specifically refractory bricks, due to its ability to improve structural integrity and performance at high temperatures.

In the firing or sintering stage, dead burned quicklime contributes to the densification of ceramic products. As it reaches high temperatures in the kiln, it decomposes, releasing carbon dioxide and leaving behind calcium oxide. This process helps bridge gaps between clay particles, resulting in improved structural integrity and reduced porosity in the final ceramic product.

Dolopel is only available from the Carmeuse Dundas location in Ontario.

How it Helps

- Extension of Refractory Lifespan – Due to the levels of calcium and magnesium and the improvements in structural integrity for ceramic products, the lifespan of the refractory is enhanced.

- Improves Heat Resistance – Dolopel supports the refractory lining's ability to better retard the heat from penetrating and damaging outer shells of steel ladles, furnaces and kilns.

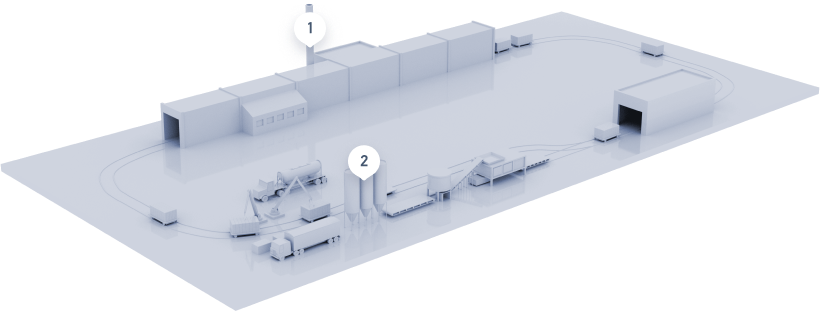

Lime or Soda Ash Storage & Conveying Systems

High volume production places high demand on your equipment. Carmeuse Systems provides comprehensive equipment and storage solutions for storage and pneumatic transfer of your bulk materials. Our experienced engineers can design tailored solutions, including new lime handling systems and retrofits or upgrades for existing equipment.

Supplying Lime for Various Applications