These raw materials are mostly produced by the sedimentation of the shells of foraminifera, brachiopods, bryozoan, snails, shellfish, corals and other organisms that took place many millions of years ago. Although the many varieties of limestone (such as chalk) and marble are indistinguishable in chemical terms, they are different from each other in many other ways. These differentiations include the material’s purity, color, thickness, hardness, homogeneity or uniformity, and crystalline forms. Calcium carbonate is a material that is as abundant as it is useful. CaCO3 is even able to be produced by combining CaO (calcium oxide) and CO2 (carbon dioxide). With many different applications for the material throughout a variety of industries, it could be argued that calcium carbonate is one of the most useful and versatile materials in existence.

The vast majority of us purposefully interact with calcium carbonate rocks for the first time in a school classroom, where we use it in the form of chalk. Chalk has been used as a writing tool for over 10,000 years and has been found in many prehistoric cave paintings as the primary medium. Chalk is a very fine, microcrystalline substance. Chalk, which is a type of biogenic rock/limestone, differs from other forms of calcium carbonate, such as limestone, by being made up almost entirely of the calcite mineral. In addition to chalk, there are many different types of limestone such as oolitic limestone, dolomitic limestone, fossiliferous limestone, pulverized limestone, marine limestone, and more. The limestone formed can be found all over the world, and is often mined in a limestone quarry. There are many large deposits of marble that can be found in both Europe and North America and also in Europe. Calcium carbonate found in its many sedimentary forms can also be transformed through natural process into marble, a metamorphic rock. This process happens when either any form of limestone is recrystallized by being subjected to high temperature and high pressure conditions over long periods of time. Some of the most famous marble comes from Carrara, Italy. Carrara is home to the pure white "statuario" marble, which was used by Michelangelo to create his famous sculptures.

The History Of Calcium Carbonate

Research and knowledge on calcium carbonate rocks has actually led to important discoveries about the history of our planet from a geological standpoint. Limestone and marble are all forms of calcium carbonate and were predominantly formed in shallow marine environments. This observation that large amounts of limestone and marble deposits that were all of a similar age had been found across the world eventually led to the discovery that at one point in time there was a period where much of the land exposed today was submerged by warm, shallow seas. Just as today, warm, shallow seas create an environment where shelled organisms flourish and having done so for millions of years explains why so much of the crust of the earth is calcium carbonate.

The earth’s crust is not the only place where calcium carbonate is found in the natural world. Calcium carbonate solutions from current deposits provide the living organisms of today with the material they need to grow their protective shells and skeletons, such as egg-laying animals. Natural eggshells consist of more than ninety percent calcium carbonate material.

Calcium Carbonate Extraction

There are different ways in which calcium carbonate can be extracted from the crust of the earth. The two main ways that we extract calcium carbonate are mining or quarrying. We can also create a man-made form of calcium carbonate. While some of the purest calcium carbonate can be obtained naturally from marble, an ulta pure form can be produced by exposing carbon dioxide to a solution of calcium hydroxide (the hydrated form of calcium oxide). Calcium carbonate is derived from the mixture of these two substances which forms a grade of product called "precipitated calcium carbonate,” otherwise known as PCC. The particle size of precipitated calcium carbonate is very fine, typically less than five microns in diameter. Precipitated calcium carbonate has proven to be useful in the production of paper products. Other than precipitated calcium carbonate, another type of industrial calcium carbonate used is called "ground calcium carbonate,” or GCC for short. Ground calcium carbonate, as the name implies, is made by taking calcium carbonate and crushing the material. The crushed material creates a substance that takes on a powdery form. Ground calcium carbonate is graded and categorized by size and other properties. Ground calcium carbonate is utilized in a wide variety of industrial, agricultural, and pharmaceutical applications that you will learn about in more detail below.

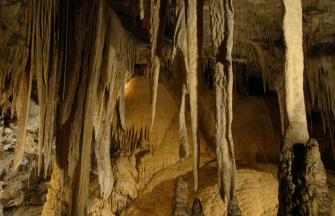

Calcium Carbonate Formations

Another important thing to note is that calcium carbonate has a unique reaction of producing carbon dioxide (CO2) when it is exposed to acids. Because this reaction is so consistent, it provides geologists and other scientists with a reliable way to test and identify if material is calcium carbonate or not. Sometimes acid is exposed to calcium carbonate naturally through precipitation and groundwater, which then dissolves and transports calcium carbonate. This natural process is vital to the formation of limestone cave systems. Dissolved calcium carbonate water continues to find its way through discontinuities and voids in the rock, slowly growing and evolving the cave system underground. We can see the lasting effects of this process through the many stalactite and stalagmite formations that are commonly found in cave systems. Stalactites and stalagmites are created when water containing calcium carbonate drips slowly in one place. Over a period of time, often thousands of years, the calcium carbonate in that water is released slowly during the natural evaporation process, leaving calcium carbonate at the source of the drip on the roof of the cave (stalactite) and some, where it falls (stalagmite).

Uses Of Calcium Carbonate

While calcium carbonate in nature can be extremely fascinating, the mineral’s impact, uses, and value to the many different industries of modern life are equally as interesting.

Plastics, Paints, And Coatings

Calcium carbonate is an extremely common material found in the production of plastics, paints and other special coatings. Calcium carbonate is used in the paint industry both as a filler and as a coating which allows for different paints. Because pure white paint is more difficult to achieve, the value that is added with the help of calcium carbonate is truly significant. The paint, plastic, and coating industries value calcium carbonate not only for its extreme brightness but also for its light scattering characteristics. Another important aspect of why calcium carbonate is so valued in the coatings industry is that the material can be used as a filler. This is often common in products such as adhesives and sealants. Calcium carbonate filler is also used in many paints and can sometimes account for up to thirty percent of a paint’s weight.

Paper Industry

Just like in plastics, paints, and coatings, calcium carbonate is a very vital material for the paper industry. Precipitated calcium carbonate is used in the paper industry both as a filler and as a coating. As pure white paper is more difficult to achieve, the value that is added with the help of calcium carbonate is truly significant. The paper industry values calcium carbonate not only for its extreme brightness but also for its light scattering characteristics. Another important aspect of why calcium carbonate is so valued in the paper industry is that the material is relatively inexpensive and can work as a filler. Filler is used in paper-making machines, and using calcium carbonate as a filler allows for the paper to not only be bright but also even and smooth.

Medical Industry

Calcium carbonate is used in the medical industry in many different ways. Common uses for calcium carbonate in the medical industry include effective dietary calcium supplements, antacids, phosphate binders, or base material for medicinal tablets. Typically in the medical field, precipitated (synthetic) calcium carbonate is used.

Food Industry

Calcium carbonate can be found on many grocery store shelves in a variety of products. Calcium carbonate can be found in products such as baking powder, toothpaste, dry-mix dessert mixes, dough, and even wine. Another important use for calcium carbonate in the food industry is agricultural lime. It is the active ingredient in agricultural lime and is many times used in animal and livestock food.

Building Products Industry

One of the most critical uses for calcium carbonate happens in the construction industry. Calcium carbonate can be used as a building material on its own, like a marble countertop for example. But calcium carbonate is also an important ingredient that can be found in cement. Calcium carbonate is a versatile industrial mineral commodity and is used in the manufacturing of mortar which is used when bonding bricks, concrete blocks, stones, roofing shingles, rubber compounds, and tiles to other surfaces.

Environmental Industry

Calcium carbonate has antacid properties, and because of this, calcium carbonate is also used in different industrial settings to neutralize acidic conditions that are commonly found in both soil and water.

Where Does Pure Calcium Carbonate Come From?

Calcium carbonate is also known as CaCO3 is a combination of calcium oxide and carbon dioxide and makes up more than 4% of the earth’s crust. Calcium carbonate is not native to any specific area and can be located throughout the world. Calcium carbonate’s most common natural forms are sedimentary rocks such as chalk and limestone, as well as metamorphic rock like marble. These sedimentary rock forms are produced by the carbonate sediments of the shells of small, fossilized snails, shellfish, and coral over millions of years.

As mentioned previously, natural calcium carbonate deposits are found in the earth’s crust and are predominantly composed of the carbonate sediments of skeletal remains of shelled marine organisms that would have been fossilized long ago. When under the right conditions, these skeletal remains build up and layer on top of each other over time forming thick layers of calcium carbonate. These deposits of natural calcium carbonate are found all over the world and they can take the form of limestone, marble, chalk or more. Because of varying geological movements and metamorphic processes in different locations across the planet, there are different forms of calcium carbonate crystallization that can occur, leading to the formation of:

Chalk: which is a very soft rock that often contains siliceous impurities and is mostly made of calcite.

Limestone: composed of sedimentary rock, it is harder and more dense than chalk and is made of a blend of calcite and aragonite.

Limestone is typically extracted from the earth’s crust either by blasting or mechanical excavation, which method is used depends on the hardness of the rock. Then the rock is crushed roughly. After crushing the stone can be sorted into different groups where they can either be used or crushed further. Limestone that is further crushed and grinded becomes a fine powder which can also be used.

Marble: is the hardest, least porous form of calcium carbonate having undergone metamorphism and it comes in many different varieties and colors.

Precipitated Calcium Carbonate: As we covered earlier, calcium carbonate also is produced synthetically in the form of precipitated calcium carbonate or simply PCC for short. The transformation process consists of decarbonating limestone, which separates the CaO and CO2. Next, these elements are recombined. The CaO and CO2 are recombined through a process that takes place with the help of a chemical reactor. The final product has the same chemical composition as calcium carbonate. While the chemical properties of precipitated calcium carbonate are the same, there are different properties that exist in terms of particle size distribution, particle shape, and purity. These physical and chemical property differentiations include:

- Brightness

- Particle Shape

- Purity

- Thermal Conductivity

- Solubility

- Alkalinity

Frequently Asked Questions

Are Calcium Carbonate And Limestone The Same Thing?

Limestone is a general name for a variety of different rock formations. Limestone is composed primarily of calcium carbonate, but not entirely.

What Is Calcium Carbonate Limestone Used For?

Calcium carbonate is used across a vast number of industries including, construction, pulp/paper, building products, medical, environmental, water/wastewater, ferrous/non-ferrous, agricultural and food industries.

Is Calcium Carbonate Made Of Limestone?

Calcium carbonate is not made of limestone. It’s actually quite the opposite. Limestone is primarily made of calcium carbonate, but not entirely. The limestone quarries operated by Carmeuse are some of the purest forms available for mining.

How Much Calcium Carbonate Is In Limestone?

In limestone, while the exact ratio of calcium carbonate can vary, the compound comprises the majority of the rock’s make-up.

What Is the Difference Between Limestone And Dolomite?

Limestone is made up of calcium carbonate, whereas dolomite is made of calcium magnesium carbonate and is less expensive than limestone. Another important difference is that sand, clay and silt are commonly found in limestone as impurities, but these impurities are less commonly found in dolomite.