Do you have a question about this application? Ask our specialists

Contact us

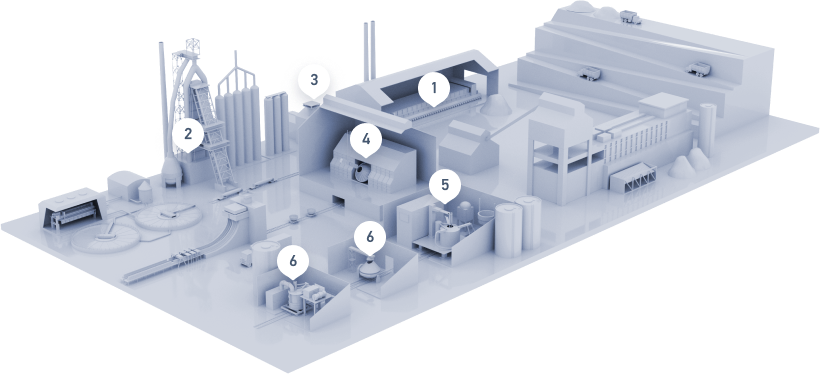

A Look at Foundry Operations

Foundry furnace operations produce metal castings. The process involves first melting the metal, then pouring it into a mold where it hardens as it cools. Removal of the casting from the mold completes the process.

In iron foundries, molten pig iron is used to manufacture cast iron. Pig iron is produced by first melting iron ore in a blast furnace. Pig iron can be used directly from that point or remelted later for use in casting. Modern steel foundry operations often use electric arc furnaces (EAF) in production.

Lime products are used in foundry operations as fluxes to reduce impurities in the molten iron and form slag. Lime addition helps protect refractories, maintain basicity and help with dephosphorization. When phosphorus and sulfur are not controlled in the steel bath, the strength may be compromised, and the finish may contain inclusions.

Our Role in Foundry Operations

What We Do

Carmeuse can help your foundry furnace operations run more smoothly by protecting your slag and refractory performance and aiding in casting removal. Carmeuse is a global leader and expert in providing lime products and lime handling system solutions for the iron and steel industry.

Carmeuse high calcium quicklime is used to support the foamy slag in an electric arc furnace (EAF), helping to remove impurities in the steel and stabilize the arc. This, in turn, extends refractory life, improves energy efficiency, and reduces power-on time and repair time. Carmeuse dolomitic lime is used to promote foaming and protect refractory lining.

Benefits

- Removing Impurities - High calcium quicklime is used as a fluxing agent to aid in efficient and effective slag formation to remove impurities like sulfur, phosphorus, and silica from the molten iron to improve steel quality.

- Maintaining Slag Viscosity – High calcium quicklime helps maintain the viscosity of the slag to increase heat yield. Proper formation of slag layer protects the refractory, concentrates and transfers heat to the liquid steel, and traps impurities and metal oxides.

- Extending Refractory Life - Magnesium content in dolomitic quicklime prevents melt-throughs in the refractory, and helps extend refractory life.

- Casting Removal – Hydrated lime can provide a lubrication to the casting process to aid in easy removal from molds.

Lime Injection and Lime Handling Systems for Foundry Furnace Operations

An evaluation of your lime handling equipment is essential in ensuring lime is transferred from silo to furnace in the most effective and reliable way, as over time this will be impacted through normal wear and tear. From offloading and flow promotion to pneumatic conveying and lime injection, Carmeuse is committed to providing quality equipment solutions to foundry furnace operations to help optimize your operations.

Carmeuse Systems supplies our advanced equipment solutions for lime storage, handling, and lime injection. Our expert engineers can design the right solution to keep your steelmaking operation running smoothly, from new lime handling or injection systems, to retrofits and upgrades for your existing equipment. Experienced technicians are also available for onsite diagnosis of current problem areas, recommendations for potential solutions, and help with system implementation and startup. For additional information related to our lime handling and lime injection expertise, visit the website.

Supplying Lime for Various Applications