Do you have a question about this application? Ask our specialists

Contact us

What is Lime Injection for EAF?

Lime injection is a method of adding lime and dolime directly into the molten steel bath of an electric arc furnace (EAF) via a powerful pneumatic injector through the side-wall of the furnace.

Historically, steelmakers have used various methods for adding lime and dolime to the electric arc furnace (EAF), including scrap bucket discharge and fifth-hole addition through the roof (via conveyor belt).

Lime injection systems are becoming increasingly popular as a more efficient means to transfer lime into molten steel. Maintaining a foamy slag in the EAF is essential but fundamentally challenging. Modern sidewall lime injection systems allow lime to be introduced into the EAF in a more controlled process, enabling slag foaminess throughout the heat cycle. Lime injection technology also provides a closed-loop environment, which enables nearly 100% of lime to be used in-process. This results in a cleaner and safer working environment with less dust in the air and on the shop floor, and a reduction in overall lime usage, which lowers your CO2 emissions. Other advantages of lime injection include better control of slag chemistry, energy savings, improved steel processing performance, and extended refractory life.

Our Role in EAF Steelmaking

What We Do

Carmeuse supports EAF steelmakers from End-2-End.

Carmeuse is a global leader and expert in providing lime products, lime handling equipment, and lime injection system solutions for Electric Arc Furnace (EAF) steelmaking. Carmeuse high calcium quicklime is used as a fluxing agent to form slag and purify the steel by removing impurities such as phosphorous, sulfur and silica. Carmeuse dolomitic lime is used to promote slag foaming and protect refractory lining, extending its useful life.

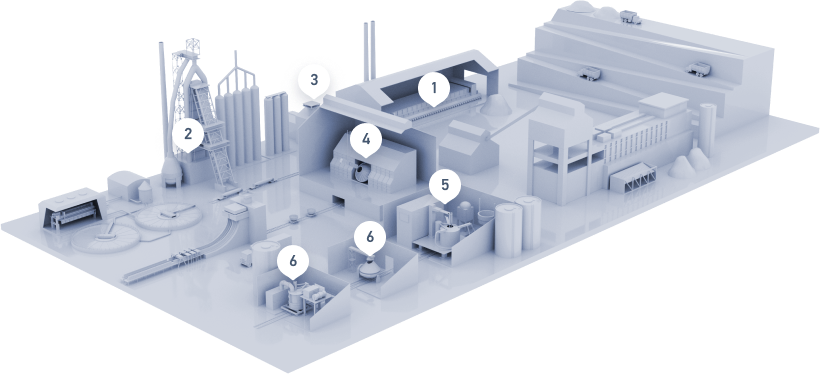

Carmeuse, along with our injection technology partners, is among some of the first lime producers to introduce lime injection technologies to EAF shops. Carmeuse's lime injection solution for EAF steel plants will be customized to meet each plant's site and lime requirements, and will include truck offloading, silo storage, pneumatic conveying, piping and controls, copper blocks, burner boxes and supersonic injectors. This system can be installed in new sites or integrated into existing sites.

How it Helps

- Removing Impurities - High calcium quicklime is used as a fluxing agent to aid in efficient and effective slag formation to remove impurities like sulfur, phosphorus, and silica from the bath and improve steel quality.

- Maintaining Slag Viscosity – High calcium quicklime helps maintain the viscosity of the slag to increase heat yield. Proper formation of slag layer protects the refractory from arc damage, concentrates and transfers heat to the liquid steel, and traps inclusions and metal oxides.

- Foaminess Control - High calcium quicklime supports foaminess throughout the heat, while dolomitic quicklime helps to optimize slag conditions for foaming. The Magnesium oxide (MgO) from dolomitic lime is especially important to the foaming characteristics of the slag. In addition to the role of the fluxing agents, lime injection systems enable more precise process control to maintain consistent foaminess.

- Extending Refractory Life - Magnesium content in dolomitic quicklime prevents melt-throughs in the refractory, and helps extend refractory life of the EAF vessel, hood, and ladle.

- Reducing Lime Loss & CO2 Emissions – The more precise injection of lime provides an optimum alternative to traditional practices of adding pebble lime, which has always been difficult to control. Lime injection allows nearly 100% of lime to be used in the steelmaking process, reducing overall lime usage and lowering CO2 emissions.

- Metallurgical Benefits – Lime injection improves the dissolution rate of lime, promotes better slag consistency, and improves dephosphorization efficiency.

- Cost Benefits – Implementing lime injection provides process improvements which can bring significant cost benefits such as a reduction in lime consumption, energy savings in the furnace, reduced electrode consumption, and extended refractory life.

Lime Injection and Lime Handling Systems for EAF Steelmaking

An evaluation of your lime handling equipment is essential in ensuring lime is transferred from silo to furnace in the most effective and reliable way, as over time this will be impacted through normal wear and tear. From offloading and flow promotion to pneumatic conveying and lime injection, Carmeuse is committed to providing quality equipment solutions to EAF steelmakers to help optimize your operations.

Carmeuse Systems supplies our advanced equipment solutions for lime storage, handling, and lime injection. Our expert engineers can design the right solution to keep your steelmaking operation running smoothly, from new lime handling or injection systems, to retrofits and upgrades for your existing equipment. Experienced technicians are also available for onsite diagnosis of current problem areas, recommendations for potential solutions, and help with system implementation and startup. For additional information related to our lime handling and lime injection expertise, visit the Carmeuse Systems website.

Supplying Lime for Various Applications