Do you have a question about this application? Ask our specialists

Contact us

The Container Glass Production Process

The production process for container glass is highly precise, with each step carefully orchestrated to create the familiar glass bottles and containers used to package a wide range of products. It typically begins with the selection of raw materials, including silica sand, soda ash, and limestone. These materials are carefully measured and mixed to form a homogeneous glass batch. The batch is then heated in a furnace to temperatures exceeding 2,000 degrees Celsius, causing it to melt and become a viscous, molten glass. This molten glass is then carefully shaped into the desired container form through various processes, including blowing, pressing, or drawing. After forming, the containers undergo a gradual cooling process to relieve internal stresses and strengthen the glass. The final products are meticulously inspected for quality and may undergo additional processes such as labeling and packaging. Container glass manufacturing demands a high level of precision to ensure that the resulting containers are not only functional but also meet the stringent standards required for a wide array of consumer and industrial applications.

Our Role in Container Glass Production

What We Do

Carmeuse produces high quality limestone that is used in the production of container glass. The use of limestone offers glass manufacturers several benefits that improve the quality of the final product by removing contaminants, improving product strength, and enhancing efficiency in the production process.

Specifically, when limestone is mixed in with silica sand, soda ash, and other raw materials it will act as a fluxing agent to modify the viscosity of the melt. It also improves the glass's transparency and optical clarity, making it suitable for showcasing the contents of the container. The addition of limestone ensures that glass containers are not only aesthetically pleasing but also durable and resistant to breakage during production and transportation.

How it Helps

- Stabilizes Silica – Limestone acts as a flux in the glass melt, stabilizing the silica content, which is the primary component of glass. This helps maintain the integrity and consistency of the glass composition.

- Reduces Melting Temperature – Limestone lowers the melting temperature of the glass batch, leading to energy savings during the manufacturing process.

- Improves Optical Clarity – It contributes to the optical clarity and transparency of the glass, making it suitable for showcasing the contents of the container.

- Enhances Durability – Glass containers produced with limestone are more durable and less prone to breakage during production and transportation.

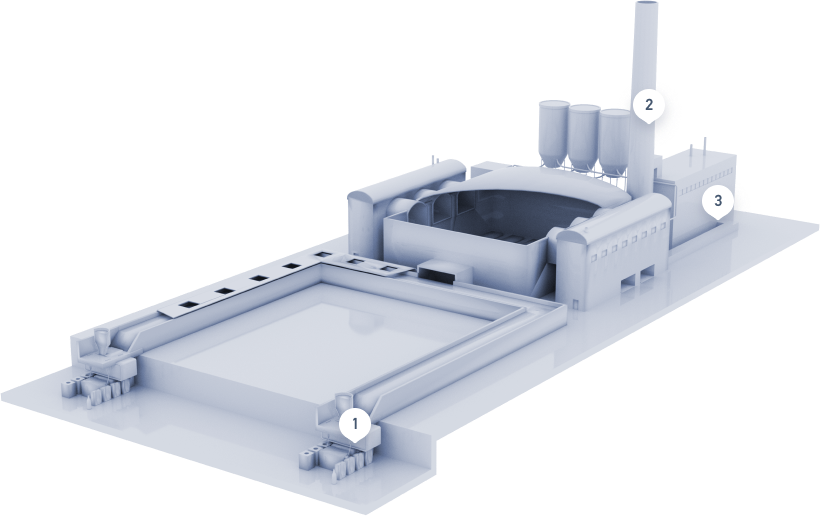

Lime or Soda Ash Storage & Conveying Systems

High volume production places high demand on your equipment. Carmeuse Systems provides comprehensive equipment and storage solutions for storage and pneumatic transfer of your bulk materials. Our experienced engineers can design tailored solutions, including new lime handling systems and retrofits or upgrades for existing equipment.

Supplying Lime for Various Applications