Lime injection is a well-established practice, used by most of the modern electric arc furnaces (EAFs). Lime injection technology provides a closed circuit environment. Its advantages include a better and safer working environment; process controls that help to maintain a consistent foaminess; a direct savings on lime; plus significant benefits from metallic yield, energy and electrode consumption, as well as refractory savings. The uniform jet of injected lime, which is shrouded with oxygen, helps to direct the lime into the slag-metal interface. This minimizes the chance of any lime particles being lost to de-dusting systems.

Carmeuse is a global leader and expert in providing lime products that meet the individual application needs in the steel industry. Along with our subsidiary, Storage & Transfer Technologies (STT), we are uniquely positioned to serve our customers from the raw material right up to the point of application. STT has been the expert in lime handling systems for over 50 years and offers one of the most effective lime injection systems for EAF steel plants.

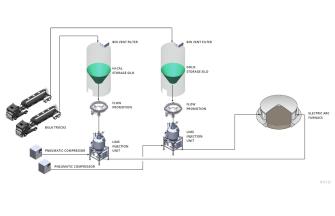

Our lime injection system stands out through a partnership with Schenck Process, who has built a strong reputation with steel manufacturers with their carbon injection systems. Together, STT and Schenck Process, along with raw material expertise from Carmeuse offers steel manufacturers an efficient solution to managing their lime application.

CHALLENGE

Improving safety and working environment for the workforce in any steel manufacturing site is of paramount importance along with optimizing cost and delivering world-class performance to the stakeholders. Given the complexity of the steel making process, every step change is a way forward to achieve desired results.

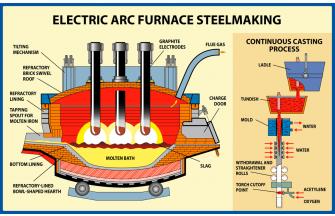

Foamy slag and its benefits are not alien to steel makers. Foamy slag increases thermal efficiency, decreases melting times and reduces energy, electrodes, and refractory consumption. To make a good foamy slag, a right balance of all slag components at the correct temperature is required. In an electric arc furnace, it is a challenge to maintain or improve the slag foaming intensity, preserving the liquid steel quality and keeping emissions at a low level.

Lime injection through side wall is designed to control the timings and flow to feed lime and help in achieving foamy slag. Lime addition, using conventional routes of scrap charging buckets or conveyors etc., does not help in balancing the components at the right time and right temperature.

SOLUTION

Lime injection is well-known and used by most of the modern EAFs. Lime injection technology provides a closed-circuit environment supporting a better and safer work environment; process controls to maintain consistent foaminess; and brings direct savings on lime (approximately 7-15%) and indirect savings on consumables.

The uniform jet of lime ensures it is directed into the slag-metal interface minimizing the chance of any lime particles being lost to de-dusting systems. This jet enables near to 100% utilization of the lime, compared to about 80% with traditional addition through buckets or conveyors using 5th hole. Modern lime injection systems are able to inject material within a controlled period, hence adding lime only when needed enabling slag foaminess during the last part of liquid steel superheat phase when the foamed slag tends to lose such status. This “tunable” control provides further savings of high-calcium or dolomitic lime, which also helps to reduce the slag volumes and dust burden on de-dusting systems.

Lime injection brings significant cost benefits from reduction in lime consumption to process benefits including improved metallic yield, reduced melting power, reduced electrode consumption, and refractory savings.

EXPERTISE

Carmeuse is a global leader and expert in providing lime products and solutions customized to individual application needs in the steel industry. We achieve this through our subsidiary STT, the experts in lime handling systems, and their partnership with Schenck Process. Carmeuse is uniquely positioned having a strong reference list and an operational lime injection pilot system capable of testing and comparing current or potential lime injection materials in multiple configurations to mimic current or potential lime injection systems in EAF.

Technical engineers as well as experienced technicians are available for onsite diagnosis of current problem areas, recommendations for solutions and help with system implementation and startup. Our trained team is capable of assisting in the evaluation, auditing, refurbishment and/or installation of lime injection equipment.

For more information on lime injection systems from our subsidiary, STT, please visit:

https://www.sttsystems.com/systems/lime-injection-systems/

This is a global offering that Carmeuse is well-positioned to support steel manufacturers. Before installing a lime injection system at your site, reach out to us to ensure your system needs are fully evaluated – from raw material to point of application.